Fiber Laser Cutting Machine Lineup

UNILASER builds industrial fiber laser cutting machines for shops that need consistent performance, reliable accuracy and steady output. Our product line covers exchange-table systems for high-volume sheet metal work, single-platform cutters for compact shops, and tube laser cutting machines for round, square and rectangular profiles.

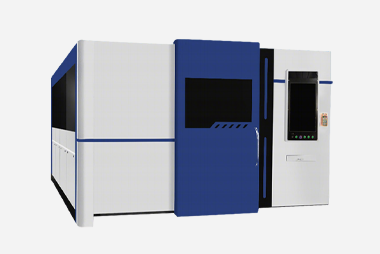

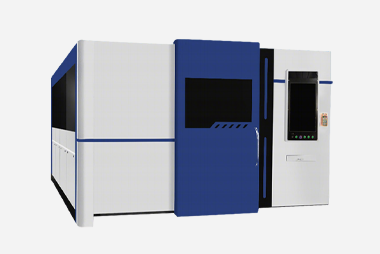

UA Series Full-Enclosure Exchange-Table Fiber Laser

High-speed, full-enclosure fiber laser cutting machine with dual exchange tables for continuous sheet metal production in 3–12 kW power range.

View UA Series Details

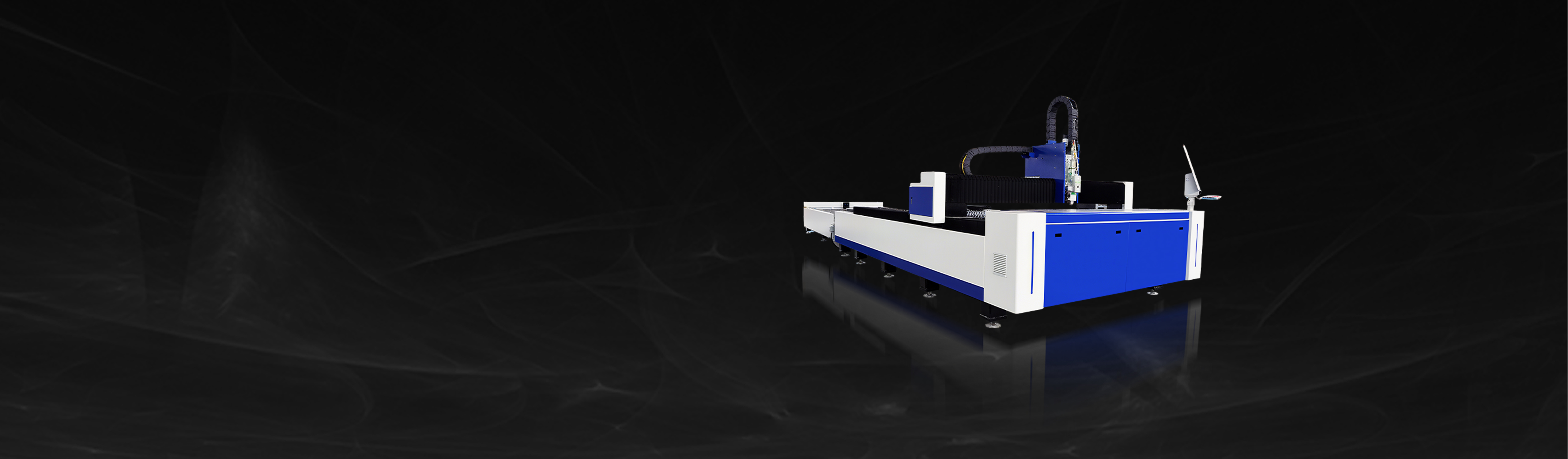

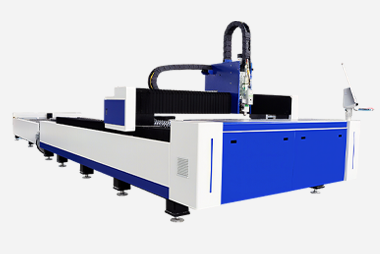

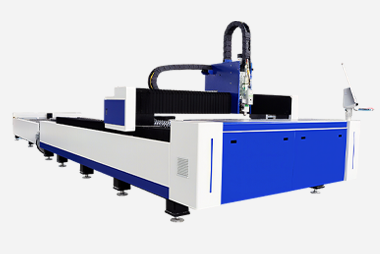

Single-Platform Fiber Laser Cutter

Compact, cost-effective fiber laser cutting machine for shops with limited floor space.

View Single-Platform Model

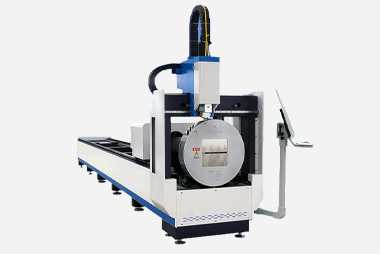

Tube Laser Cutting Machine

Dedicated tube laser cutter for round, square and rectangular tubes used in multiple industries.

View Tube Cutting Models

Compact Square & Round Tube Cutter

Economic tube cutting solution with small footprint and simple operation.

See Compact Tube Cutter

Automation & Custom Integration

Custom loading, unloading, storage and line integration solutions for fiber and tube laser cutting systems.

Discuss Automation ProjectBuilt for Precision. Engineered for Production

With over a decade of tube-laser expertise, UNILASER builds machines for accuracy, stability and real production demands. Our self-developed control system and industrial-grade cutting head deliver ±0.3 mm precision, clean edges and reliable long-cycle performance.

Real Production Samples & Industry Applications

UNILASER supports a wide range of cutting needs: tube structures, metal panels, frames, brackets, decorative pieces and custom components used in furniture, automotive, HVAC, construction and equipment manufacturing.

About Us

UNILASER has specialized in industrial laser cutting systems since 2009, supplying sheet-metal and tube-fabrication industries with reliable, high-precision fiber laser solutions. Our 30,000 m² factory and 2,000-unit annual capacity support stable, large-scale production.

With 15+ years of experience and over 150 patented technologies, we develop our own control software, motion algorithms and industrial-grade components to ensure consistent accuracy and long-term stability.

All systems comply with CE, FDA, and FCC standards and are manufactured under ISO 9001:2015, guaranteeing safe, high-quality performance across automotive, furniture, HVAC, construction and general fabrication sectors.

Contact Us

Tell us briefly about your materials, thickness and production needs. Our engineers will get back to you within 24 hours.

Latest News & Industry Insights

Stay updated with new applications, customer cases and product insights from real manufacturing environments.